Electrification of U.S. Manufacturing With Industrial Heat Pumps

Authors: Jibran Zuberi, Ali Hasanbeigi, William Morrow

Thermal processes in U.S. manufacturing are responsible for approximately two-thirds of the total final energy demand. Decarbonization of industrial heat demand through electrification could contribute significantly to climate change mitigation efforts. Cross-cutting electrification technologies that are applicable to a range of industrial processes without needing major modifications to the existing infrastructure may facilitate the clean energy transition in the industry.

Electric-driven heat pumps are among those technologies that are suitable for process heat supply to several industrial unit operations in a sustainable manner while also improving overall energy efficiency. However, despite a promising alternative for an efficient and emission-free supply of process heat at technically feasible temperatures in industrial processes, the industrial heat pumps (IHP) deployment in the U.S. has been limited.

Currently, there is a lack of studies in the literature focusing on wide-scale applications of industrial heat pumps in U.S. manufacturing. To address these literature gaps, the objectives of this work are

i) to review the current state-of-the-art and real-life applications of industrial heat pumps globally,

ii) to analyze the technical, economic, and energy-saving and CO2 reduction potentials of the industrial heat pumps technology’s wide-scale deployment in several U.S. manufacturing sectors under different energy supply and price scenarios,

iii) to identify the drivers and barriers to implementation and provide action plans to overcome the barriers.

We conducted the closed-loop industrial heat pump application analysis for the following industrial subsectors: meat processing, dairy, beer, canned vegetable and fruit processing, cane sugar refining, beet sugar, corn wet-milling, soybean oil, textile spinning and weaving, textile wet processing, pulp and paper, and automotive industries.

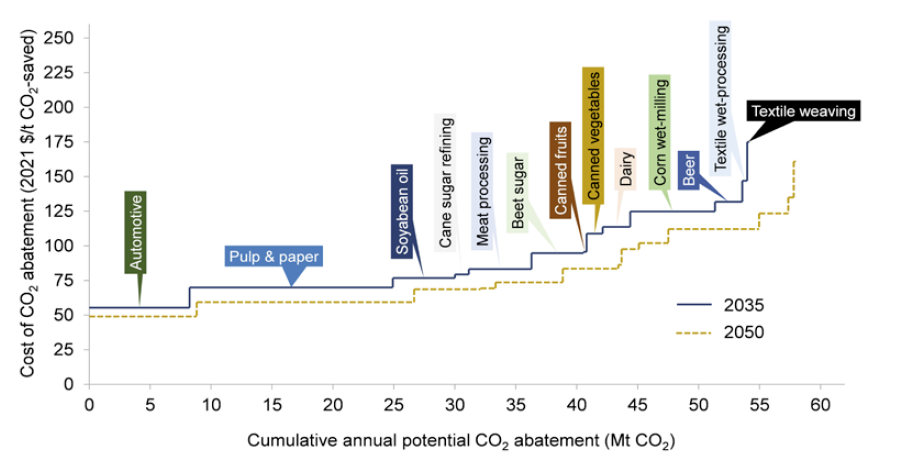

CO2 abatement cost curves and energy conservation cost curves are developed to estimate the marginal costs and the technical potentials for CO2 emissions reduction and energy savings from IHP applications, respectively. The results show that despite the current average U.S. electricity grid emission factor being higher than the emission factor of natural gas, electrifying hot water and steam generation systems in the thirteen industrial processes studied can already decrease the annual CO2 emissions by around 17 Mt CO2 per year in the base year 2021, assuming a 100% adoption rate of industrial heat pumps applications. However, given the fact that electricity grids will be further decarbonized and potentially fully decarbonized in 2050, the magnitude of total CO2 abatement potential is projected to be 58 Mt CO2 per year in 2050 (equivalent to 5% of the total greenhouse gas emissions from U.S. manufacturing), as shown in Figure 1.

The CO2 abatement costs in different industrial processes range between 49 and 160 $/tCO2 in 2050. Since the coefficient of performance (COP) of industrial heat pumps application with a high-temperature lift (i.e. difference between heat source and heat sink temperatures) is typically low, the CO2 abatement costs in industrial sectors with few or no applications requiring high-temperature lifts (i.e. greater than 100 K) are found to be relatively less expensive (e.g. in the automotive industry as shown in Figure 1). This means that high-temperature heat sources must be first utilized for heat sinks with the highest temperatures to minimize the temperature lifts and operational costs and maximize heat pump COPs.

Figure 1. CO2 abatement cost curve for industrial heat pumps applications in U.S. manufacturing (Source: this study).

As far as the rankings of the CO2 abatement costs for each sector are concerned, multiple factors, including current process-specific boiler efficiencies, industrial heat pumpss COPs, required IHP capacities, and the corresponding investment and operational costs affect the marginal costs of IHP applications in U.S. manufacturing sectors. One of the major reasons for the high abatement costs is the disparity between the electricity and fuel prices in the U.S. industry. For example, the average electricity price in the U.S. industry (i.e. 70 $/MWh) is almost five times higher than the average price of natural gas (i.e. 14 $/MWh) in 2021. The assumed heat source temperature i.e. 25C is another factor influencing the costs to be high and it is recommended to explore and utilize suitable waste heat sources at higher temperatures to minimize the temperature lifts and consequently reduce the electricity costs.

Despite the large potential for energy and CO2 emissions reduction in U.S. manufacturing, there are several barriers associated with the wide-scale applications of IHP. To address these challenges, key and targeted actions, including further research, development, demonstration, and deployment (RDD&D), policy interventions, workforce development, and capacity building, are needed. Detailed action plans are provided by the authors that different stakeholders could take to facilitate the applications of IHP in industrial processes where suitable in U.S. manufacturing.

To read the full report and see complete results and analysis of this new study, Download the full report from the link above.