Electrification of Heating in the Textile Industry

A Techno-Economic Analysis for China, Japan, and Taiwan

December 2022

Revision 1 – June 2024

Authors: Ali Hasanbeigi and Jibran Zuberi

The textile and apparel industry currently accounts for approximately 2% of global anthropogenic greenhouse gas (GHG) emissions. The sector has been growing rapidly in recent years due to increasing demand from both developed and developing countries and world population growth, which will increase its environmental and climate impacts unless effective steps are taken to abate them. For these reasons, the textile and apparel sector is keenly interested in identifying and implementing opportunities to reduce its carbon and environmental footprint.

As is the case in many other industrial sectors, a key challenge for the textile industry in lowering its carbon footprint is its heavy reliance on thermal energy – steam and hot water – for its industrial processes; heating typically represents over half of its total energy demand in the textile industry in China, Japan, and Taiwan, which are the economies studied in this report. In textile plants, this heat is often delivered as steam that is primarily generated by combustion boilers using fossil fuels. A significant amount of thermal energy is lost during steam generation and distribution (around 25%-30%).

There is a significant opportunity to decarbonize the textile and apparel sector by shifting heat production away from inefficient and carbon-intensive fossil fuels to more efficient, clean electrified processes where low- or zero-carbon electricity is used. Based on careful investigation of the different heat demand profiles in the textile processes and the electrification technologies available in the marketplace to meet those heating needs, this report identifies and analyses four separate electrification pathways with the ability to lower the CO2 footprint of the textile industry. We quantify the potential energy savings, CO2 emissions reductions, and costs of each technology pathway in each of the three economies studied.

The four electrification technology pathways analyzed are:

1) Industrial heat pumps (only for the textile wet-processing industry)

2) Electric steam boilers (for the entire textile industry)

3) Electric thermal oil boilers (for the entire textile industry)

4) Electric processing equipment (only for seven textile wet-processing processes)

Our results show that electrification can substantially decrease the total annual final energy demand in the textile industry in these three economies under all four electrification technology pathways. For example, the total technical annual energy saving potential through the application of industrial heat pumps in textile wet-processing plants (assuming a 100% adoption rate) is estimated to be around 270, 7.0, and 7.3 petajoules (PJ) per year in China, Japan, and Taiwan, respectively. This is equal to around one-third of the total fuel used in the textile industry in these three economies. The substantial reduction in annual final energy demand is due to the increase in energy efficiency with electrified heating systems and the reduction in energy losses that happen in conventional combustion heating systems.

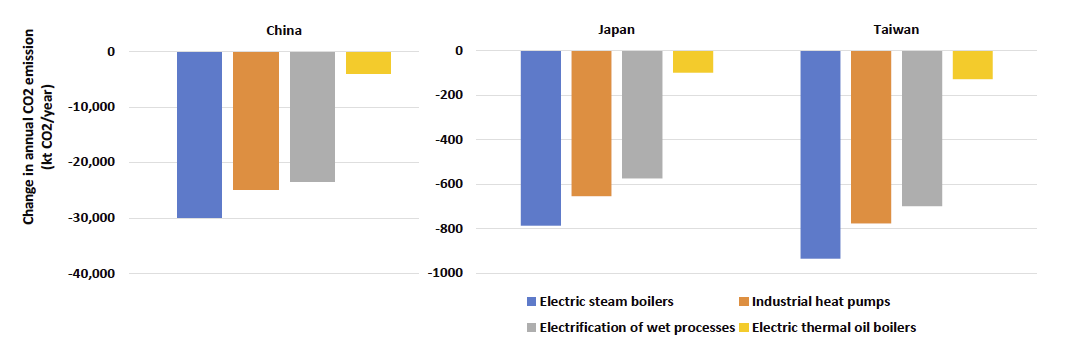

The CO2 emissions impact resulting from the electrification is highly dependent on the carbon intensity of the electricity used with the electrified process. Figure ES1 shows the CO2 emissions reductions resulting from electrification under each of the four electrification technology pathways in 2050. For example, the total annual CO2 emissions reduction potential from 100% adoption of electric steam boilers or industrial heat pumps in the Chinese textile industry is around 29.8 and 24.9 million tonne (Mt) CO2 per year in 2050, respectively. These are equal to approximately 59% and 49% of total fuel-related annual CO2 emissions from the textile industry in China in 2021.

Figure ES1. The change in annual CO2 emissions after the electrification of the textile industry in 2050

(Notes: Figure shows the technical potential assuming a 100% adoption of industrial heat pump applications. Negative values imply a reduction in annual CO2 emissions)

For more information and resources on decarbonizing the textile and apparel industry, don’t forget to check our Textile Sustainability Hub website.

If the average national grid electricity is used, only electrification of the textile industry through industrial heat pumps can result in CO2 emissions reduction in 2030 in all three economies. This is because of the substantial reduction in energy use that these heat pumps provide. Electrification of wet processes can result in CO2 emissions reduction in 2030 in Taiwan and Japan, but not in China, a disparity that reflects the greater carbon intensity of the grid in China compared to the other two economies. Electrification of steam boilers and electric thermal oil boilers could initially lead to an increase in annual CO2 emissions in all three economies in 2030. This is because the assumed average electricity grid emission intensity for these three economies in 2030 will be high and the grid is not decarbonized enough to result in CO2 emissions reduction from the electrification of boilers despite the reduction in final energy use. However, electrification is projected to result in a substantial reduction in annual CO2 emissions in 2040 and 2050 under all electrification technology pathways as the grid decarbonizes and becomes carbon neutral in 2050.

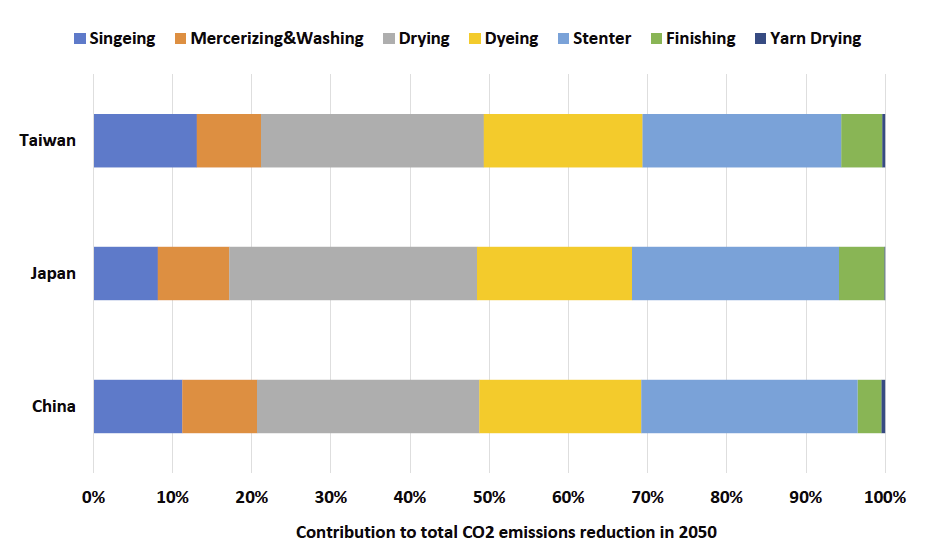

Our analysis for electrification through textile end-use processes shows that around 75% of the CO2 emissions reduction potential in 2050 comes from the electrification of three processes: drying, dyeing, and heat-setting (stenter) (Figure ES2). Around half of the emissions reduction potential comes from the electrification of drying and heat-setting processes. The equipment with electrified heating for these two processes are already commercially available and they can be good candidates to start with for end-use process electrification in textile plants.

Figure ES2. Contribution of each textile wet processes electrification (in end-use electrification scenario) to total CO2 emissions reduction in 2050

It should be noted, however, that in practice, electrification projects will happen at the plant level. If a given textile plant in any country electrifies its process heating demand today and purchases renewable electricity (e.g., through a power purchase agreement (PPA)) to supply the electricity demand of the electrified process heating, the CO2 emissions reductions from electrification can be achieved immediately. Therefore, our country-level results should not be interpreted in a way that electrification cannot be beneficial now, and we should wait until the electricity grid is decarbonized.

Our analysis also evaluated the cost of the electrification of the four technology pathways; these cost calculations focus only on energy costs and do not include the capital costs associated with purchasing new equipment. Only in the case of industrial heat pumps the energy cost per unit of production of electrified systems is lower than the conventional systems by 2030. This outcome again reflects the fact that heat pumps substantially reduce energy use compared to conventional systems. For the other three electrification technology pathways, the electrified processes have higher energy costs per unit of production compared to the conventional process in the near term. But under all pathways, the electrified process will have a lower energy cost in 2050 compared to conventional systems. In the best case, the price of renewable electricity may decrease even more rapidly than we have assumed, and/or the price of fossil fuels may increase more substantially, which would accelerate the electrification of heating.

It should be noted that the energy cost is only a small portion (5%-15%) of the total manufacturing cost in the textile industry. A moderate increase in energy cost per unit of the product resulting from electrification will have a minimal impact on the price of the final textile and apparel products.

We also provide some key recommendations that can be taken by the textile industry, policymakers, and others to scale up electrification in the textile and apparel industry and accelerate CO2 emissions reductions.

To read the full report and see complete results and analysis of this new study, Download the full report from the link above.

For more information and resources on decarbonizing the textile and apparel industry, don’t forget to check our Textile Sustainability Hub website.

Also, Follow us on LinkedIn, Facebook, and Twitter to get the latest about our new blog posts, projects, and publications.